Introduction to solar cell bussing machine

The solar cell bussing machine is a critical component in the production of solar panels. It is responsible for connecting individual solar cells in series to form a solar cell string, which is then encapsulated in a solar panel. The bussing process involves applying a conductive paste to the front and back of each solar cell and then pressing the cells together to form a string.

The solar cell bussing machine has evolved over the years, from manual labor-intensive processes to fully automated machines that can produce solar cell strings at a high speed and with high precision. These machines are equipped with advanced technologies such as vision systems, laser cutting, and infrared heating to ensure that the bussing process is efficient and reliable.

The solar cell bussing machine is a significant investment for solar panel manufacturers, but it is essential for producing high-quality solar panels that meet industry standards. With the increasing demand for renewable energy and the declining cost of solar panels, the solar cell bussing machine has become a vital piece of equipment in the solar panel production line.

Working principle of solar cell bussing machine

The solar cell bussing machine is an essential piece of equipment in the solar panel manufacturing process. Its primary function is to connect individual solar cells in series to form a solar cell string, which is then encapsulated in a solar panel. The bussing process involves applying a conductive paste to the front and back of each solar cell and then pressing the cells together to form a string.

The solar cell bussing machine operates on a simple principle. First, the solar cells are fed into the machine on a conveyor belt. The machine then applies a conductive paste to the front and back of each cell using a screen printing process. The conductive paste is usually made of silver or aluminum and is essential for creating a conductive connection between the cells.

Once the paste is applied, the machine uses a press to compress the cells together, forming a string. The press applies a uniform pressure to ensure that the cells are tightly bonded together. The machine then cuts the string to the desired length and prepares it for the next stage of the manufacturing process.

The solar cell bussing machine is highly automated and can produce solar cell strings at a high speed and with high precision. It is equipped with advanced technologies such as vision systems, laser cutting, and infrared heating to ensure that the bussing process is efficient and reliable.

In conclusion, the solar cell bussing machine is a vital piece of equipment in the solar panel manufacturing process. Its working principle is simple but highly efficient, and it plays a crucial role in producing high-quality solar panels that meet industry standards.

Benefits of using a solar cell bussing machine

In recent years, the demand for solar energy has increased significantly, leading to a rise in the production of solar panels. One of the critical steps in manufacturing solar panels is the bussing process, where individual solar cells are connected in series to form a solar module. The solar cell bussing machine automates this process, providing several benefits to manufacturers.

Increased efficiency

The solar cell bussing machine is designed to operate at high speeds, significantly reducing the time required for the bussing process. Traditional manual bussing methods are labor-intensive and time-consuming, resulting in lower production rates. By automating this process, manufacturers can increase their production capacity and meet the growing demand for solar panels.

Improved accuracy

One of the significant advantages of using a solar cell bussing machine is the improved accuracy it provides. Manual bussing methods are prone to human error, leading to misaligned cells and poor-quality solar panels. The bussing machine uses advanced technology, such as vision systems and laser alignment, to ensure that each cell is accurately positioned and connected. This precision results in higher-quality solar panels with better performance and longer lifespans.

Reduced labor costs

Automating the bussing process with a solar cell bussing machine can significantly reduce labor costs for manufacturers. Manual bussing requires skilled workers to perform repetitive tasks, which can be expensive and time-consuming. The bussing machine requires minimal human intervention, allowing manufacturers to reallocate their workforce to other critical areas of production, further reducing labor costs.

Consistent quality

Consistency is crucial in solar panel manufacturing, as even minor defects can impact the performance and reliability of the final product. The solar cell bussing machine provides consistent quality by using automated processes and advanced technology to eliminate variations caused by human intervention. This consistency ensures that each solar panel meets the required industry standards and performs as expected.

Flexibility and customization

Modern solar cell bussing machines are designed to be flexible and customizable, allowing manufacturers to adapt to changing market demands and produce a wide range of solar panels. These machines can handle various cell sizes, shapes, and configurations, enabling manufacturers to produce solar panels tailored to specific customer requirements. This flexibility allows manufacturers to stay competitive in the ever-evolving solar energy market.

Features of a solar cell bussing machine

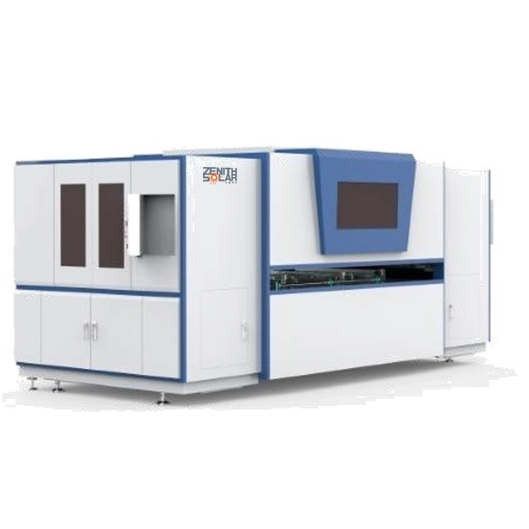

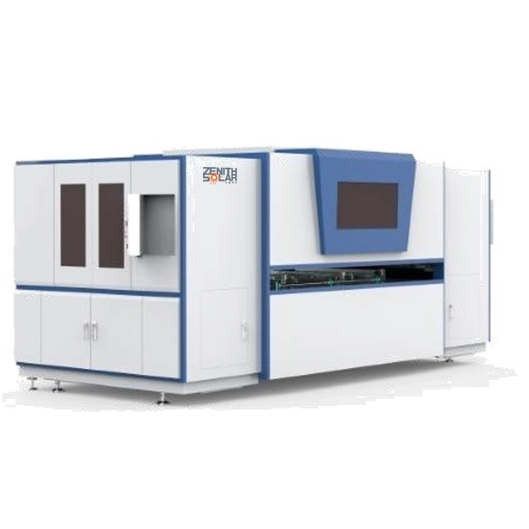

The solar cell bussing machine is a critical piece of equipment in the solar panel manufacturing process. It automates the process of connecting individual solar cells in series to form a solar module, providing several benefits to manufacturers. This article will discuss the key features of a solar cell bussing machine that make it an essential tool for solar panel production.

High-speed operation

One of the most significant features of a solar cell bussing machine is its high-speed operation. These machines are designed to work at a much faster rate than manual bussing methods, significantly reducing the time required for the bussing process. This increased efficiency allows manufacturers to produce more solar panels in less time, meeting the growing demand for renewable energy.

Automated processes

The solar cell bussing machine is fully automated, eliminating the need for manual intervention in the bussing process. This automation reduces the risk of human error, ensuring that each solar cell is accurately positioned and connected. The machine also automatically cuts and sorts the solar modules, further streamlining the production process.

Advanced technology

Solar cell bussing machines are equipped with advanced technology to improve the accuracy and efficiency of the bussing process. One such technology is the use of vision systems, which ensure that each solar cell is correctly aligned before being connected. Laser alignment systems also ensure that the cells are accurately positioned, reducing the risk of misaligned cells and improving the overall quality of the solar panels.

Customizable settings

Modern solar cell bussing machines are designed to be flexible and customizable, allowing manufacturers to adapt to changing market demands and produce a wide range of solar panels. These machines can handle various cell sizes, shapes, and configurations, enabling manufacturers to produce solar panels tailored to specific customer requirements. The bussing machine’s settings can also be adjusted to accommodate different bussing materials and methods, providing further flexibility in the production process.

Compact design

Despite their advanced technology and high-speed operation, solar cell bussing machines are designed to be compact and space-efficient. This compact design allows manufacturers to easily integrate the bussing machine into their existing production lines without requiring significant modifications. The machine’s small footprint also makes it an ideal solution for manufacturers with limited production space.

Conclusion

In conclusion, the solar cell bussing machine is a critical piece of equipment in the solar panel manufacturing process. Its high-speed operation, automated processes, advanced technology, customizable settings, and compact design make it an essential tool for producing high-quality solar panels efficiently and cost-effectively. As the demand for renewable energy continues to grow, the solar cell bussing machine will play a vital role in meeting this demand by enabling manufacturers to produce solar panels at a higher rate and with improved quality.