As the global demand for renewable energy continues to surge, solar photovoltaic (PV) systems have taken center stage. Among the many factors influencing the success and cost-efficiency of solar energy is the long-term durability of solar panels. While the solar cells themselves are responsible for converting sunlight into electricity, the surrounding materials and assembly processes are what protect the cells over decades of exposure to sun, wind, rain, and temperature fluctuations.

One of the most crucial machines involved in this protective process is the solar laminator. Though it operates out of sight in manufacturing lines, its contribution to a solar module’s reliability is enormous. A properly laminated solar panel resists moisture, heat, and mechanical stress for 25 years or more. In contrast, a poorly laminated panel can suffer from early performance degradation, delamination, or even electrical failure. This article explores how solar laminators work, what role they play in ensuring long-term durability, and why their design and operation are vital to the entire PV industry.

Understanding the Basic Role of a Solar Laminator

A solar laminator is a specialized machine that fuses the multiple layers of a photovoltaic module into a single, sealed unit. At its core, the laminator’s job is to bond the encapsulant, solar cells, glass front sheet, and backsheet using heat and pressure in a vacuum environment. This process is known as lamination, and it happens in a controlled cycle that ensures every panel is uniformly sealed against external environmental elements.

Each PV module typically includes five to seven layers: starting with the top layer of tempered glass, followed by an encapsulant film (usually EVA or POE), the solar cells themselves, another encapsulant layer, and finally the protective backsheet. During lamination, these layers are compressed and heated so that the encapsulant softens, flows around the cells, and cures into a gel-like adhesive. The result is a completely enclosed panel that protects internal components from oxygen, humidity, and physical stress.

Without this lamination step, even the best-quality solar cells would degrade rapidly in real-world conditions. The laminator ensures that all layers are permanently sealed together, forming the core structural integrity of a solar panel.

Lamination and Its Impact on Panel Lifespan

The longevity of a solar module depends heavily on its ability to maintain structural and electrical integrity over time, even under harsh outdoor conditions. This is where the lamination process becomes critical. A high-quality lamination process prevents air and water ingress, which are leading causes of corrosion and electrical insulation breakdown. It also keeps the cells aligned and mechanically stable, reducing the risk of microcracks and other long-term mechanical damage.

If a panel develops delamination—a condition where one or more layers separate—it can trap moisture and lead to discoloration, hot spots, or even arc faults. Delamination often results from poor bonding due to insufficient heat, uneven pressure, or incorrect vacuum levels during lamination. This not only affects performance but may also void warranties, increasing replacement costs and project downtime.

Therefore, the performance of the solar laminator directly influences the life expectancy of the module. A robust lamination step ensures that PV modules can survive 25 to 30 years of weather exposure, temperature cycling, mechanical stress, and ultraviolet radiation without suffering performance loss.

Technological Advancements in Solar Laminators

Modern solar laminators have evolved significantly from earlier manual systems. Today’s equipment is engineered with advanced thermal management, multi-zone heating, precision vacuum systems, and automated control algorithms that enable consistent, repeatable quality. These advancements reduce human error and ensure that each module receives the optimal curing profile.

One major upgrade is the multi-stage lamination cycle, which allows different heating and cooling zones to be activated at precise times. For example, the initial vacuum phase removes air pockets and moisture, followed by gradual heating that activates the encapsulant. Cooling phases then stabilize the bond. The laminator must tightly control all of these transitions to prevent defects such as bubbles, blisters, or uneven flow of the encapsulant.

Some advanced models feature dual-stage or inline laminators that speed up the process while maintaining high quality. These machines increase throughput for high-volume manufacturers without compromising durability. Others come with PLC and HMI control systems that allow operators to adjust lamination recipes based on the type of encapsulant material or panel configuration.

In addition, innovations like infrared heaters, closed-loop temperature control, and thermal profiling ensure that every square centimeter of the panel receives uniform heat. This uniformity is critical for ensuring a strong bond across the entire surface, particularly for larger or bifacial modules that use transparent backsheets.

Material Compatibility and Lamination Conditions

Not all encapsulants or backsheet materials behave the same under heat. Therefore, solar laminators must be able to accommodate a range of materials with different melt temperatures, viscosity, and curing profiles. EVA (Ethylene Vinyl Acetate) has traditionally been the go-to material, but newer alternatives like POE (Polyolefin Elastomer) are being adopted for better UV and moisture resistance.

For these materials to function optimally, the laminator must deliver precise pressure and vacuum levels, typically in the range of 100-150 mbar, with heating up to 150°C or more. The curing time, temperature ramp rates, and pressure uniformity must be matched to the material being used. Even slight deviations can compromise adhesion, leading to bubbling or poor electrical insulation.

Many laminators are now equipped with recipe management systems that store different profiles for different module types. This makes it easier for manufacturers to switch between production runs without recalibrating the machine manually. The result is greater process stability and material performance, two crucial ingredients for long-term module durability.

Quality Control and Testing in Lamination

Lamination is not a one-time task—it is a process that must be consistently monitored and tested to ensure that each module meets reliability standards. Manufacturers often perform post-lamination inspections, including EL (electroluminescence) imaging, to detect hidden cracks or bonding voids.

Other common tests include peel tests (to measure adhesion strength), thermal cycling (to simulate outdoor conditions), and damp heat testing (to expose the module to moisture and elevated temperatures). Panels that pass these tests are far more likely to maintain performance over decades.

The quality of lamination also plays a major role in a panel’s warranty. Most PV module warranties last between 25 to 30 years, but that warranty is only meaningful if the lamination process is consistent and verifiable. As such, the solar laminator becomes not just a tool for manufacturing but a guarantor of long-term value for customers and installers alike.

The Role of Solar Laminators in High-Efficiency and Specialty Modules

As the solar industry shifts toward high-efficiency and specialty modules, such as bifacial, half-cell, and tandem junction panels, the demands placed on the laminator grow more complex. These advanced module types are often more sensitive to heat, and their structural configurations may require special encapsulation techniques.

For example, bifacial panels use glass-glass structures instead of traditional backsheet configurations. This requires laminators that can handle double glass thickness, apply uniform heat from both sides, and avoid damaging transparent encapsulants. In some cases, low-temperature lamination profiles are used to protect sensitive cell structures or coatings.

Laminators also need to be modular and upgradable to handle emerging technologies. This includes the ability to work with new encapsulants, flexible substrates, or ultra-thin glass sheets. A future-proof laminator should not only meet today’s manufacturing demands but also accommodate tomorrow’s innovations without requiring full replacement.

Laminator Performance and Its Impact on ROI

Solar panels are long-term assets, and any manufacturing defect can significantly reduce their return on investment (ROI). A poorly laminated panel might degrade after just a few years, forcing the owner to replace or repair modules and lose revenue. Conversely, a well-laminated panel maintains its performance for decades, increasing energy yield and reducing maintenance costs.

The choice of laminator affects not just product quality but also production efficiency. Downtime, recalibration, and scrap rates can add up quickly. Investing in a high-quality, reliable laminator reduces operational risk and helps maintain steady output in high-volume environments. In this way, the solar laminator becomes a core contributor to financial stability in module manufacturing.

Conclusion: The Quiet Backbone of Solar Panel Quality

Though rarely seen outside the factory, the solar laminator is at the heart of producing reliable and long-lasting photovoltaic modules. It transforms a fragile stack of materials into a sealed, unified structure that can survive two or more decades in outdoor conditions. Without a precision lamination process, even the best solar cells would be vulnerable to damage, inefficiency, or premature failure.

From basic bonding to material-specific lamination profiles and advanced quality control, the laminator plays a defining role in solar module durability, safety, and performance. For any solar panel manufacturer aiming to deliver high-quality products, investing in the right lamination equipment is not just a necessity—it’s a competitive advantage.

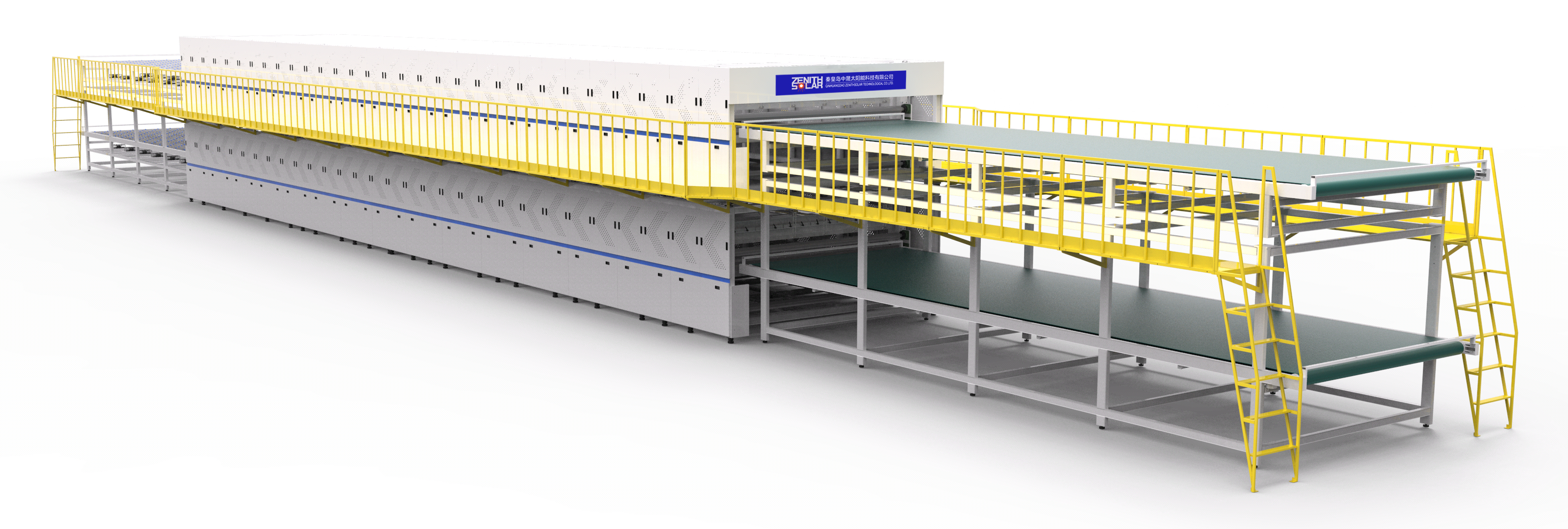

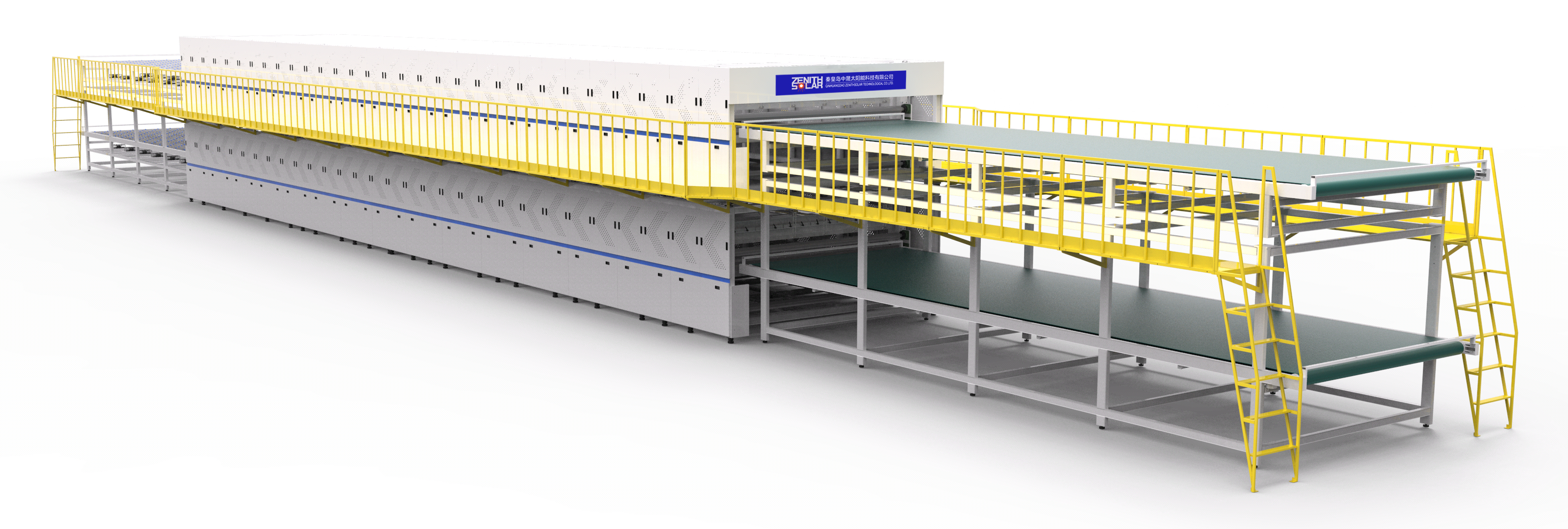

For companies looking to enhance their solar production capabilities, Qinhuangdao ZENITHSOLAR Technological Co., Ltd. offers a trusted range of modern solar laminators tailored for today’s demanding manufacturing environments. With a strong focus on innovation, precision, and support, ZENITHSOLAR helps PV manufacturers deliver high-performance modules built to last.